FDA Manufacturing Requirements: What You Need to Know About CGMP and Inspections

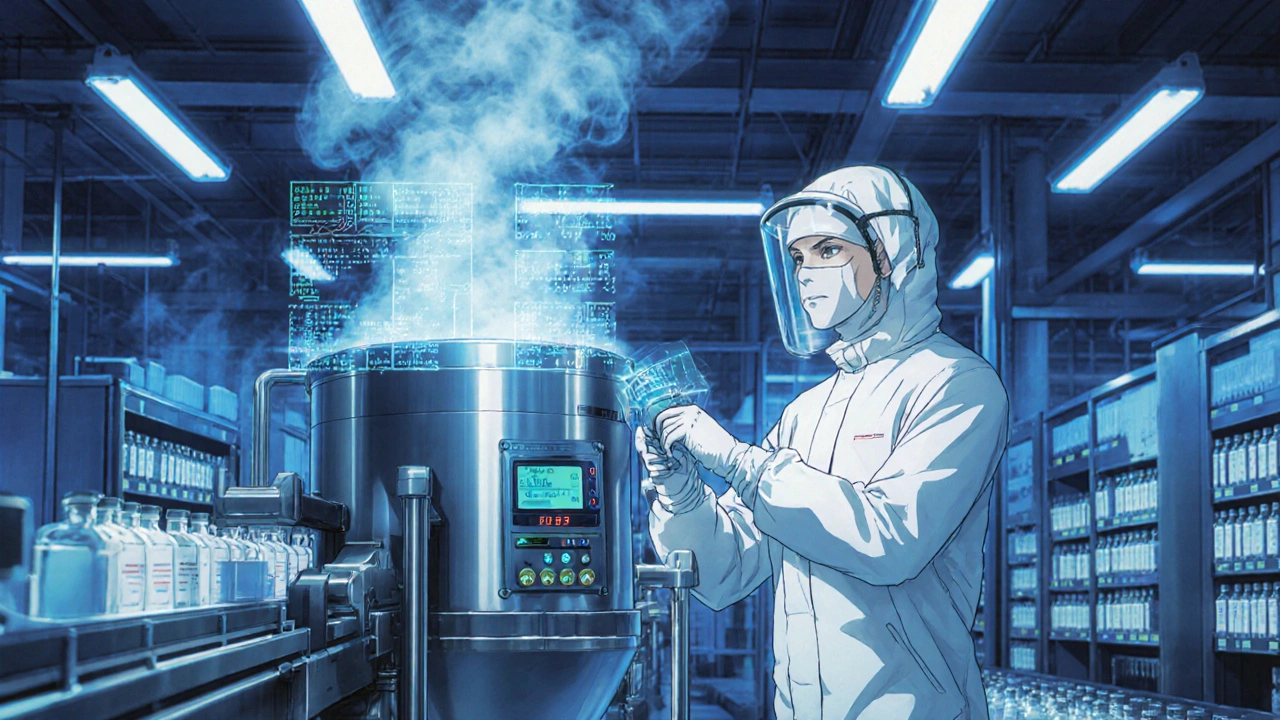

When you take a pill, you expect it to work—and to be safe. That’s not luck. It’s because of FDA manufacturing requirements, the strict rules drug makers must follow to produce medicines that are pure, potent, and consistent. Also known as Current Good Manufacturing Practices, or CGMP, these rules are enforced by the U.S. Food and Drug Administration to make sure every batch of medicine meets the same high standard. Without them, a pill could be weak, contaminated, or even dangerous. And it’s not just about big pharma—generic drug makers, contract labs, and even small-scale producers all have to follow the same rules.

The FDA doesn’t just ask companies to follow the rules. They send inspectors to check. These inspectors look at six key systems: quality control, production, facilities, equipment, laboratory controls, and materials handling. If something’s off—like data being changed, sterile rooms being breached, or raw materials not being tracked—they write it down on an FDA 483 form. That’s not a fine. It’s a warning. And if the same problems keep happening, the FDA can shut down production entirely. In 2025, the most common issues? Poor aseptic practices, falsified records, and weak controls over starting materials. These aren’t minor slips. They’re serious risks to patient safety.

It’s not just about avoiding penalties. Companies that get CGMP right build trust—with regulators, with pharmacies, and with patients. When the FDA approves a generic drug, they don’t just check the active ingredient. They check how it’s made. That’s why the 80-125% bioequivalence rule exists: to prove the generic behaves the same way in your body as the brand-name version. But that rule only works if the manufacturing process is solid. If the lab data is unreliable, the whole approval falls apart.

And it’s not just the U.S. The FDA’s standards influence how drugs are made around the world. If a factory in India or China wants to sell to Americans, it has to pass an FDA inspection. That’s why so many posts focus on what happens during those inspections—what documents they ask for, how they test samples, and how companies prepare. It’s also why you’ll see warnings about online pharmacies selling drugs from unapproved facilities. Those products bypass the FDA manufacturing requirements entirely. And that’s where counterfeit pills, wrong doses, and toxic contaminants come from.

Below, you’ll find real examples of what goes wrong in drug manufacturing, how inspections uncover it, and what companies do to fix it. You’ll also see how these rules connect to everyday issues—like why your generic pill works, why some drugs get pulled from shelves, and how to spot unsafe online sellers. This isn’t theory. It’s what’s happening now, in real facilities, affecting real medicines.

GMP for Generics: FDA Requirements for Manufacturing Generic Drugs

FDA's CGMP requirements ensure generic drugs are as safe and effective as brand-name versions. Learn the exact rules manufacturers must follow, common violations, and how compliance keeps millions of prescriptions safe.

Detail