SOPs in Pharma: What They Are and Why They Matter for Safety and Compliance

When you think about how a pill gets from a factory to your medicine cabinet, you might picture scientists in lab coats or machines humming on a production line. But behind every step is something quieter, less visible, and just as critical: a standard operating procedure, a documented set of step-by-step instructions that ensure consistency, safety, and compliance in pharmaceutical operations. Also known as SOPs, these aren’t just paperwork—they’re the backbone of every FDA-approved drug process.

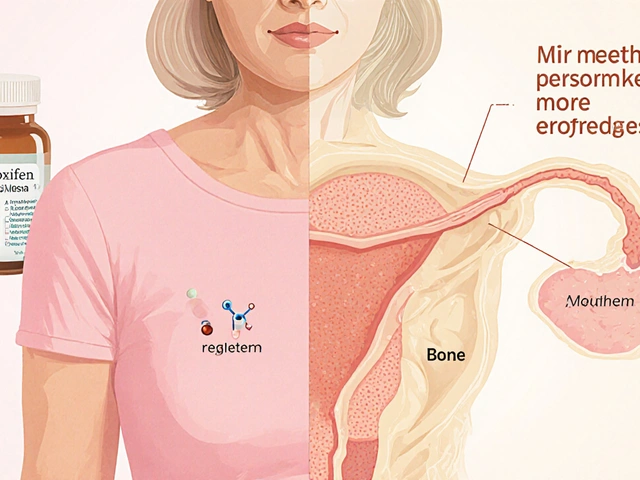

SOPs cover everything from how a pharmacist checks a controlled substance prescription to how a lab cleans equipment between batches. They’re not optional. If a pharmacy or manufacturer skips an SOP, they risk legal penalties, product recalls, or worse—harm to patients. The CGMP, Current Good Manufacturing Practices, the FDA’s mandatory rules for drug quality requires SOPs for every key activity. That includes verifying dosages, handling expired meds, storing insulin, or even disposing of acetazolamide. Without SOPs, there’s no way to prove a generic drug is as safe as the brand name, or that a night-shift worker isn’t given the wrong sedative because someone forgot to follow protocol.

And it’s not just about manufacturing. SOPs guide how pharmacists use PDMP, Prescription Drug Monitoring Programs, databases that track controlled substance prescriptions to prevent abuse before filling a script. They tell you how to read a Medication Guide, an FDA-mandated document that explains serious risks and monitoring steps for certain drugs so you don’t miss a warning about QT prolongation or serotonin syndrome. SOPs are why you can trust that your blood thinner is labeled right, that your insulin isn’t contaminated, and that your compounding pharmacy didn’t skip sterilization steps because they were rushed.

This collection of posts doesn’t just talk about drugs—it talks about the systems that keep those drugs safe. You’ll find real-world examples of SOPs in action: how pharmacists verify DEA numbers, why data integrity matters during FDA inspections, what happens when a manufacturer skips aseptic controls, and how to spot when a generic drug doesn’t meet the 80-125% bioequivalence rule. These aren’t theoretical rules. They’re the lines that separate a life-saving treatment from a dangerous mistake.

Whether you’re a pharmacist, a patient on multiple meds, or just someone trying to understand why your prescription costs what it does, SOPs are the hidden structure holding it all together. Below, you’ll find detailed guides on exactly how these procedures work in practice—and what happens when they don’t.

Documentation Requirements for Record-Keeping in Manufacturing: What You Must Do to Stay Compliant

Learn the essential documentation requirements for manufacturing under GMP standards. Understand what records to keep, how to avoid costly compliance failures, and what regulators are looking for in 2025.

Detail