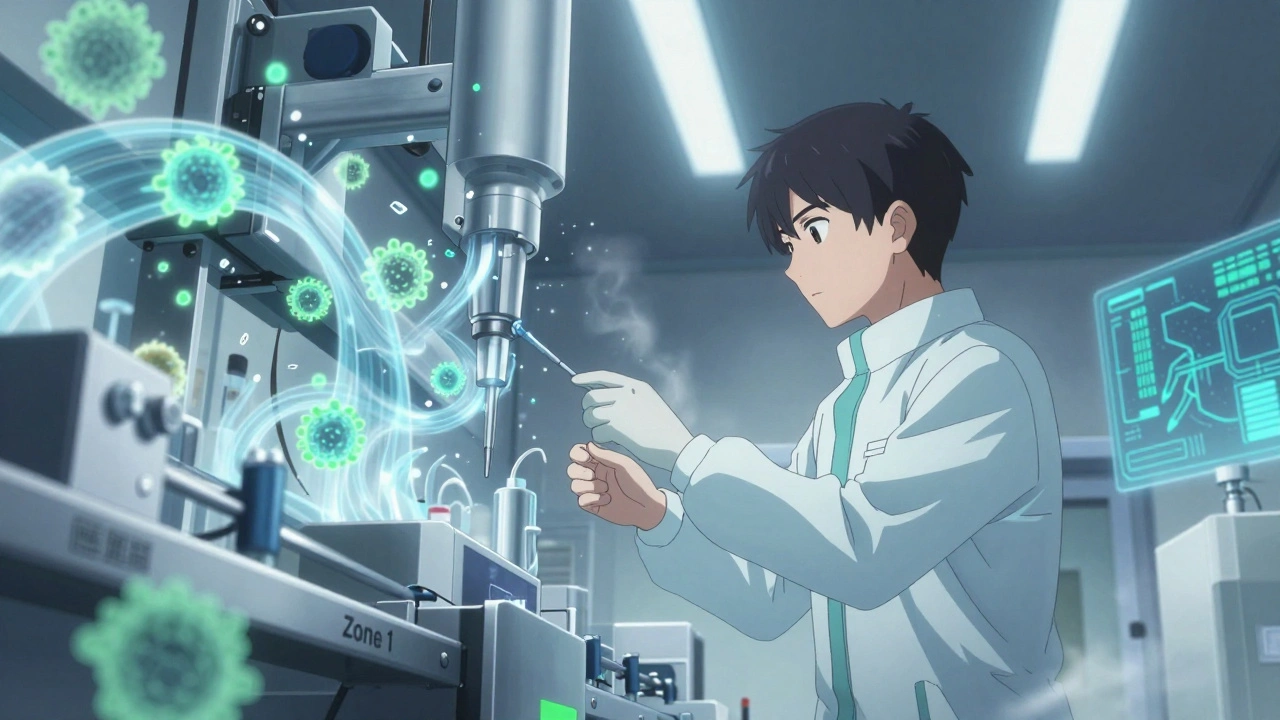

Zone Classification in Pharmaceutical Manufacturing: Standards, Compliance, and Safety

When you take a pill, you expect it to be pure, safe, and exactly as it should be. That’s not luck—it’s the result of zone classification, a system that divides pharmaceutical manufacturing areas into controlled environments based on contamination risk. Also known as cleanroom classification, it’s the backbone of every generic drug made today. Without it, even a tiny speck of dust or a stray microbe could turn a life-saving medicine into a health hazard.

Zone classification isn’t just about cleanliness—it’s about control. The FDA and global regulators like the EU require strict separation between areas where raw ingredients are handled, where pills are pressed, and where final packaging happens. Each zone has its own rules: air filters, gowning procedures, humidity limits, and even how people move through the space. A Level A zone, for example, is where sterile injectables are filled—think surgical theater conditions. A Level D zone might be where boxes are labeled, but even there, dust and personnel movement are tightly managed. These zones aren’t arbitrary; they’re based on science, and they’re enforced during FDA inspection, a rigorous review of manufacturing practices to ensure drugs meet quality standards. Miss a zone requirement, and your facility could be shut down.

Behind every GMP compliance, the set of rules ensuring pharmaceutical products are consistently produced and controlled according to quality standards checkmark is a zone classification system. It’s what links everything: how a pharmacist verifies a controlled substance, how a compounding pharmacy avoids contamination, and why the FDA flags data falsification in manufacturing. When you see a post about CGMP violations or aseptic breaches, it’s almost always tied to a failure in zone control. Even something as simple as a worker skipping a gowning step in the wrong zone can lead to a batch recall.

Zone classification also affects cost and access. If a manufacturer can’t maintain the right zone standards, they can’t make the drug—and that leads to shortages. That’s why compounding pharmacies, bulk buyers, and even patients relying on generic meds all depend on these invisible rules. It’s not glamorous, but it’s essential. What you find below is a collection of real-world guides that show how zone classification connects to everything from manufacturing defects to medication safety. You’ll see how it impacts how drugs are made, how they’re checked, and why some pills cost less while still being just as safe. These aren’t theory papers—they’re the practical truths behind every pill you take.

Environmental Monitoring: Testing Facilities for Contamination in Manufacturing

Environmental monitoring detects contamination in manufacturing facilities through air, surface, and water testing. Learn how zone classification, sampling methods, and real-time data help prevent product recalls and ensure consumer safety.

Detail