CGMP Guidelines: What You Need to Know About Pharmaceutical Quality Standards

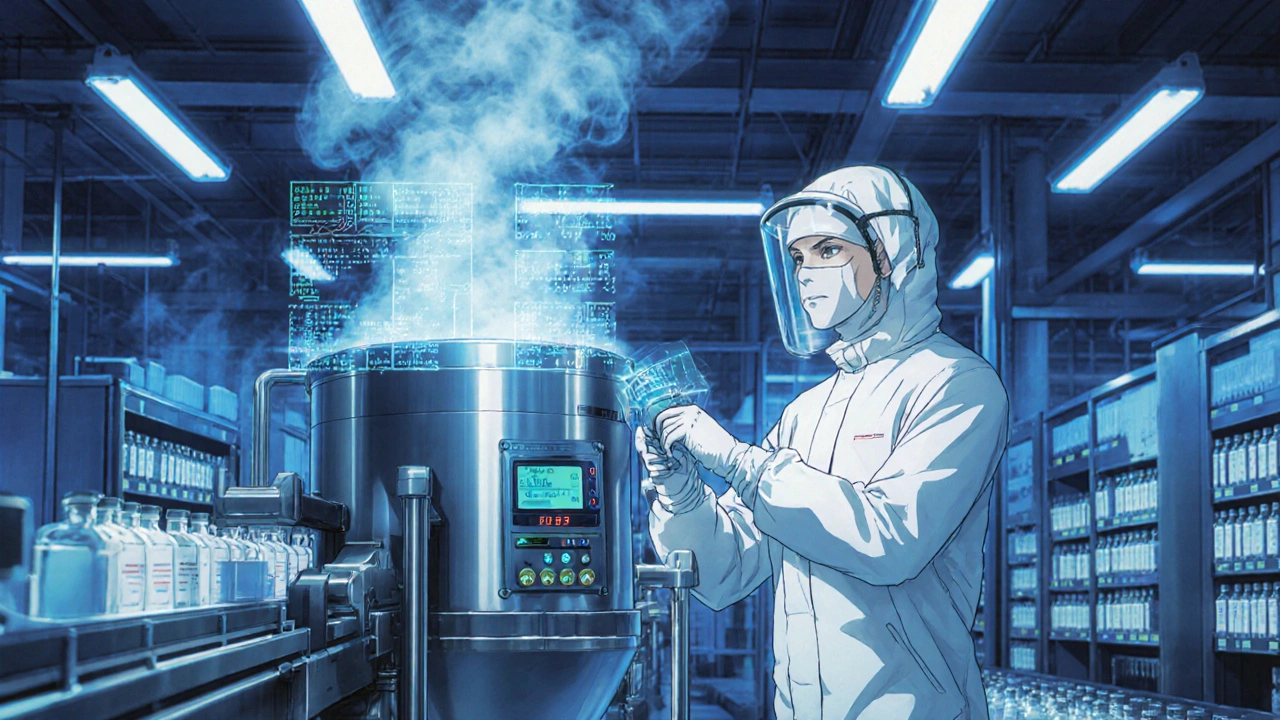

When you take a pill, you expect it to work the same way every time—that’s where CGMP guidelines, Current Good Manufacturing Practices that set the minimum standards for how drugs are made, tested, and controlled. Also known as cGMP, these rules aren’t suggestions—they’re enforced by the FDA to stop contaminated, weak, or wrong drugs from reaching you. If a company skips a step in cleaning equipment, mislabels a batch, or fakes test results, they’re breaking CGMP. And the FDA doesn’t just warn them—they shut down production.

CGMP guidelines cover everything from the raw materials used to the air quality in the factory. For example, if a sterile injectable drug is made in a room with airborne particles, that’s a violation. If a technician writes down results after the fact instead of during testing, that’s data falsification—a top reason for FDA warnings in 2025. These rules exist because one mistake can poison people. Think of it like a recipe: if you skip a step, the dish fails. In pharma, failing a step can kill.

Companies that follow CGMP aren’t just avoiding fines—they’re building trust. The same standards apply whether you’re making a cheap generic or a brand-name drug. That’s why FDA inspections, rigorous reviews of manufacturing sites that check six key systems like quality control, equipment, and recordkeeping are so strict. They look at how you train staff, how you clean machines, even how you store ingredients. And if you fail? You get an FDA 483 form listing every issue. Ignore it, and your factory gets blocked from selling in the U.S.

It’s not just about paperwork. Real people rely on these rules. A single batch of bad insulin or contaminated antibiotics can cause hospitalizations or death. That’s why CGMP isn’t just about compliance—it’s about survival. The posts below show exactly what goes wrong when these rules are broken: data falsification, aseptic failures, poor material controls. You’ll see how companies get caught, what the FDA finds, and how to fix it before it’s too late.

Whether you work in pharma, manage a clinic, or just want to know your medicine is safe, understanding CGMP helps you ask the right questions. The collection here doesn’t just explain the rules—it shows you what happens when they’re ignored, and how to spot the red flags before it’s too late.

GMP for Generics: FDA Requirements for Manufacturing Generic Drugs

FDA's CGMP requirements ensure generic drugs are as safe and effective as brand-name versions. Learn the exact rules manufacturers must follow, common violations, and how compliance keeps millions of prescriptions safe.

Detail