Manufacturing Documentation: What You Need to Know About FDA Compliance and Drug Quality

When you pick up a prescription, you expect it to work the same way every time. That consistency isn’t luck — it’s the result of manufacturing documentation, a detailed, auditable record of every step taken to produce a medicine, from raw ingredients to sealed bottles. Also known as pharmaceutical batch records, this documentation is the backbone of CGMP, Current Good Manufacturing Practices enforced by the FDA to ensure drugs are consistently produced and controlled according to quality standards. Without it, there’s no way to prove a drug is safe, effective, or even made in a clean environment.

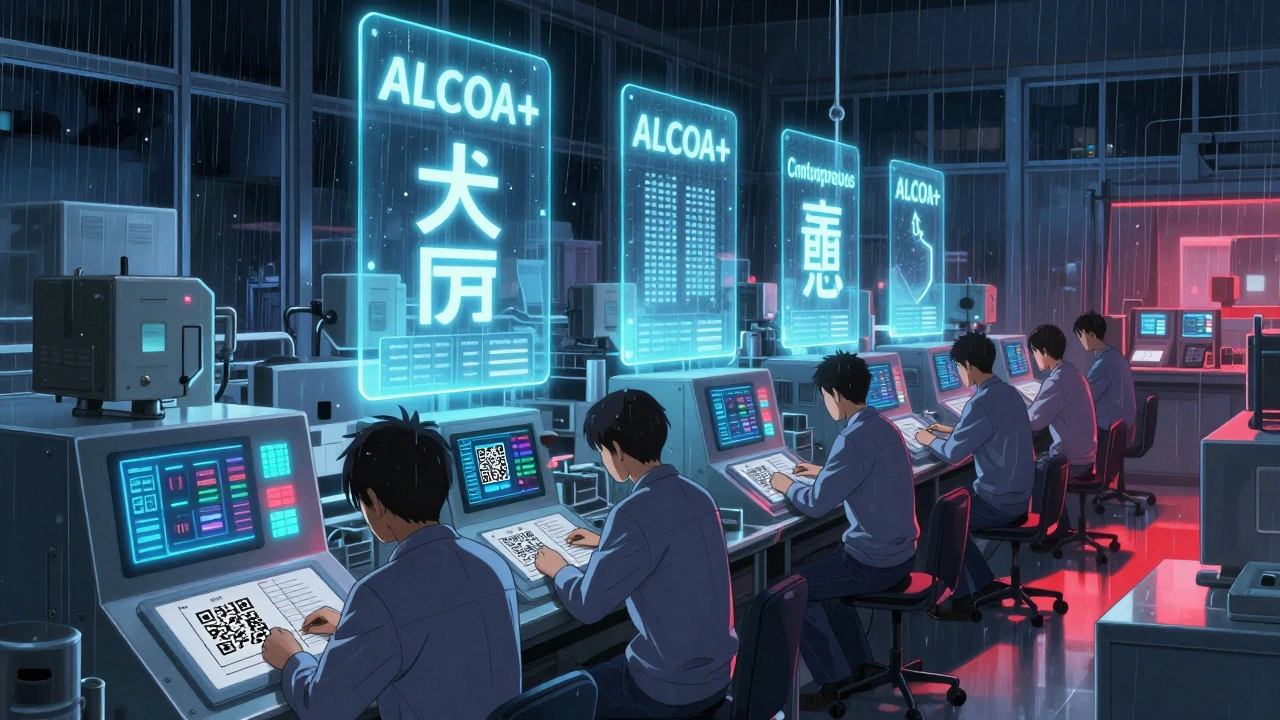

Manufacturing documentation isn’t just paperwork. It’s a living system that tracks everything: who mixed the batch, when the equipment was cleaned, what temperature the room held, and whether every tablet met weight and potency specs. If a batch fails, this paper trail tells you why — and how to fix it. The FDA checks this daily. In 2025, the most common violations weren’t about missing labels — they were about data integrity failures, when records are altered, deleted, or never created in the first place. Fake logs, backdated entries, and ignored alarms aren’t just unethical — they’re illegal. And when they happen, entire factories get shut down, and patients get unsafe meds.

It’s not just about avoiding penalties. Good documentation keeps you safe. Think about generic drugs. The 80-125% rule, the bioequivalence standard that lets generics replace brand-name drugs, only works if the generic is made under the same strict controls as the original. That’s why the FDA inspects generic factories just like brand-name ones — and why manufacturing documentation is the proof they demand. If the documentation is sloppy, the drug might not dissolve right, might have impurities, or might not work at all. You won’t know until it’s too late.

And it’s not just big pharma. Compounding pharmacies, small labs, even online suppliers — if they’re making medicine for people to swallow, they need documentation. That’s why when your medication disappears from shelves, and you turn to a compounding pharmacy, you’re trusting their records as much as their chemists. The same rules apply: clean room logs, ingredient certificates, stability testing notes. Skip the docs, and you’re gambling with your health.

Below, you’ll find real examples of what goes wrong — and what goes right — when manufacturing documentation is handled well or ignored. From FDA inspection checklists to how data falsification gets caught, these posts show you exactly how the system works, where it breaks, and why every step matters. You’re not just reading about rules. You’re learning how to spot when something’s off — and what to ask for when your life depends on a pill being exactly right.

Documentation Requirements for Record-Keeping in Manufacturing: What You Must Do to Stay Compliant

Learn the essential documentation requirements for manufacturing under GMP standards. Understand what records to keep, how to avoid costly compliance failures, and what regulators are looking for in 2025.

Detail