GMP for Generics: What You Need to Know About Quality Standards

When you buy a generic drug, you expect it to work just like the brand-name version. That’s only possible because of GMP for generics, Good Manufacturing Practices that ensure every pill, capsule, or injection meets strict quality, safety, and consistency standards. Also known as CGMP, these rules aren’t optional—they’re the backbone of every generic drug approved in the U.S. and around the world. Without them, a tablet from one factory could be weak, contaminated, or even dangerous. The FDA doesn’t just check labels—they dig into how the drug is made, from the raw ingredients to the final packaging.

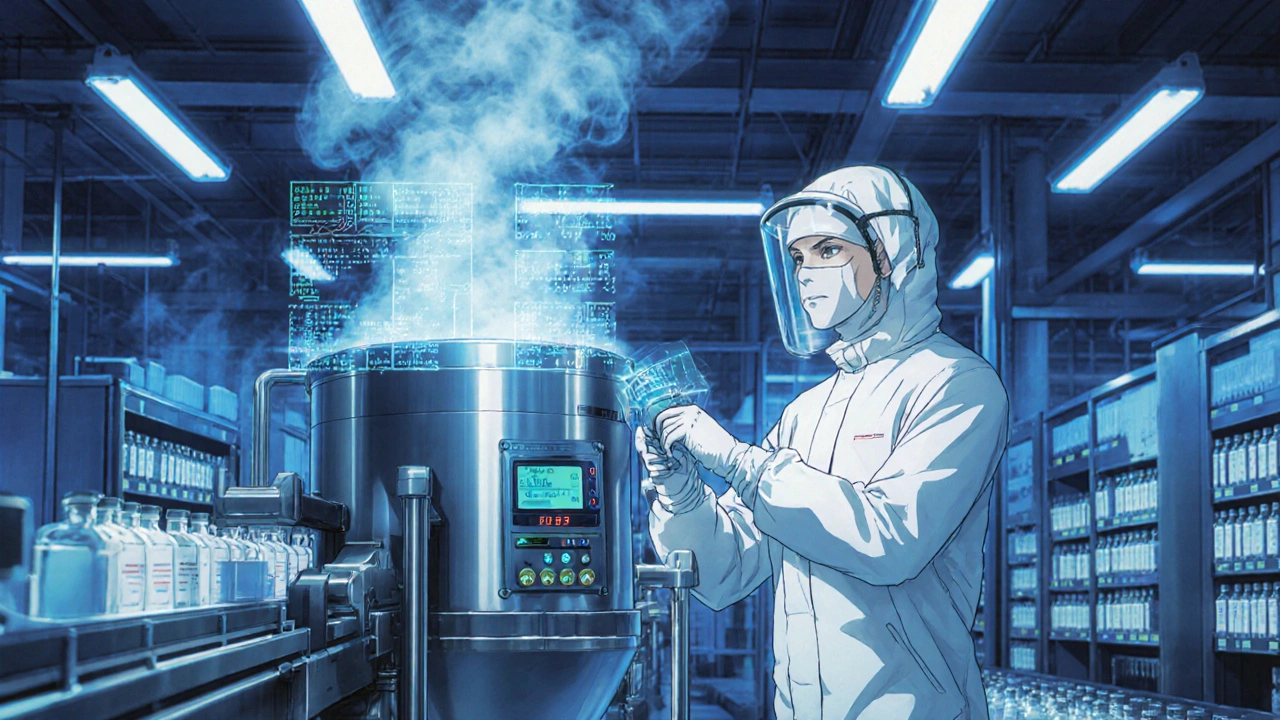

Behind every safe generic drug is a system built on CGMP compliance, a set of enforced guidelines covering everything from clean rooms and equipment validation to employee training and data integrity. Also known as current Good Manufacturing Practices, this isn’t about paperwork—it’s about control. If a lab doesn’t properly track batch numbers, or if a technician skips a sterilization step, that’s a violation. And in 2025, the FDA is catching more of these failures than ever before, especially in facilities making complex generics like injectables or controlled substances. Generic drug manufacturing, the process of producing non-branded medicines that are chemically identical to brand-name drugs, relies entirely on this system. One mistake in the mixing tank, one uncalibrated machine, one falsified log entry—and the whole batch could be unsafe. That’s why inspections are so intense. The FDA doesn’t show up with a checklist and leave. They do a six-system review: quality, production, facilities, equipment, laboratory controls, and materials. They check for data integrity issues, aseptic breaches, and whether the right ingredients were even used. The FDA inspection, a thorough, unannounced audit of drug manufacturing sites to verify compliance with regulatory standards can shut down a factory for months—or ban it from selling in the U.S. entirely.

What does this mean for you? If you take a generic version of your blood pressure pill, antidepressant, or antibiotic, you’re relying on GMP to make sure it works. It’s not about price—it’s about trust. The 80-125% bioequivalence rule ensures the drug behaves the same in your body, but that only matters if the drug was made right. A generic isn’t just a cheaper copy—it’s a medicine that had to pass the same quality bar as the original. And with more people using generics than ever, the pressure on manufacturers to get it right has never been higher.

Below, you’ll find real examples of what goes wrong—data falsification, dirty equipment, poor storage—and what happens when companies cut corners. You’ll also see how inspections work, what inspectors look for, and how these rules protect you from dangerous mistakes. This isn’t theory. These are the rules keeping your medicine safe.

GMP for Generics: FDA Requirements for Manufacturing Generic Drugs

FDA's CGMP requirements ensure generic drugs are as safe and effective as brand-name versions. Learn the exact rules manufacturers must follow, common violations, and how compliance keeps millions of prescriptions safe.

Detail